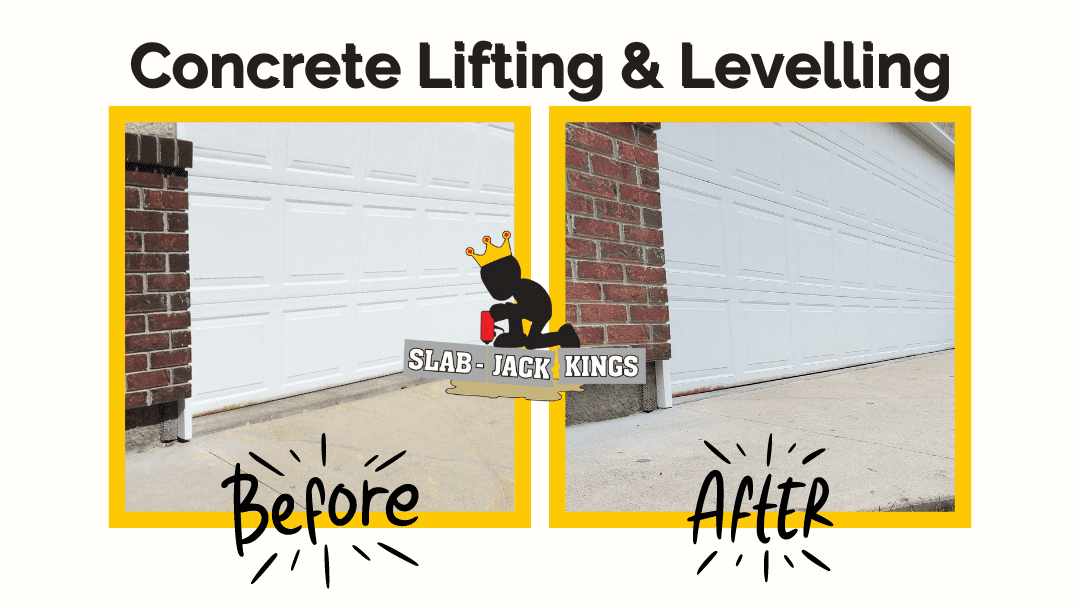

Concrete Lifting & Levelling

Polyurethane concrete raising is a more affordable alternative to concrete removal and replacement and a less invasive option compared to mudjacking. This method is less disruptive and offers several advantages over traditional slab raising techniques. At Slab-Jack Kings, our concrete lifting technicians are trained experts with over 10 years of hands-on experience. We provide concrete lifting and leveling services using various concrete raising foam systems, tailored to each project’s needs.

Slab-Jack Kings uses a unique concrete raising foam exclusive to our company, ensuring superior results. Our foam is unrivalled in compressive strength and hydrophobic, designed specifically for our climate and soil characteristics.

Once our foam infiltrates the voids and air spaces beneath the slab, it adheres permanently, strengthening it considerably. This results in:

1. a drastically reduced incidence of surface hairline cracking from ground movement and

2. minimized emerging tripping points at significant gaps and cracks where rebar is absent or failing.

Our service areas include Winnipeg and its surrounding areas, most of Manitoba, and most of Northwestern Ontario.

What is Polyurethane Concrete Lifting?

Concrete lifting and levelling is the cost-effective, eco-friendly alternative to busting out concrete. Concrete lifting, concrete raising, slab jacking or concrete leveling can usually be done for less than half the cost of pouring new concrete. However, the savings may be even greater, since when concrete raising, the costs of demolition, removal, and landscaping are eliminated.

Polyurethane concrete lifting (our personal favourite) achieves the same results as traditional mudjacking, but with a lightweight material that requires smaller and fewer injection holes and generally a longer lasting result. Also known as foam jacking/poly lifting/foam lifting, polyurethane concrete raising is the latest and greatest concrete repair method available.

Are there other terms for polyurethane concrete lifting or do they all mean different things?

Yes, there are other terms for polyurethane foam concrete lifting, and they generally refer to the same process. Terms such as polyurethane foam concrete raising, concrete raising with foam, foam jacking, foam concrete lifting, concrete lifting with foam, concrete leveling with foam, poly leveling, polyurethane slab jacking, foam lifting and foam slab jacking, etc. all describe the method of using polyurethane foam to lift and stabilize concrete slabs. These terms are interchangeable and highlight the use of concrete lifting foam in the repair process.

The Concrete Lifting Process

On the day of your job, injection holes are strategically drilled into the concrete slab that requires lifting, void filling or under-slab insulation. Our equipment is contained in a trailer, and has sufficient length of hose to accommodate almost any location. Our equipment remains parked, while our crew pulls out enough hose to reach the area being repaired.

Polyurethane foam that is engineered for concrete lifting is injected as a two-part liquid beneath the slab. The foam jacking material will infiltrate all air spaces to fill voids, and raise it to the correct level. Our lifting techs are equipped with a vast knowledge of all of the products and concrete construction in general in order to work with this specialty equipment and products.

The concrete lifting foam has an average reaction time of 12 seconds. Within those 12 seconds, the foam travels in about a 6-foot diameter beneath your concrete, throughout the voids & expands in a slow and controlled fashion.

Our lifting technician will “bunny hop” from hole to hole in order to lift your concrete slab to avoid breaking it. With use of our specialty equipment, knowledge and experience this is extremely rare.

Post-Lift

After the injections are complete, the holes are patched with a fibre-reinforced patching material that is matched closest to the colour of your concrete. Concrete lightens with age due to UV-ray exposure, and the same goes for our fibre-reinforced patching compound.

Customers may have broken areas of concrete needing to be patched, or gaps in between adjacent slabs that need to be filled for preventative measures. Depending on the width and length of the crack, break or gap, the material used is decided at the time of the estimate. Each product will be priced out accordingly. This part of the job is weather-permitting. If it’s raining outside, patching and caulking must be left until the sun is shining.

The average driveway or sidewalk repair typically takes a 1-2 hours based on the scope of the project. Garage floors, basement floors and most interior floors can take up an entire work day depending on the size of the lift and the voids we cannot see beneath. Each and every job is different.

…At last, your concrete slab is ready for use immediately after our crew is done!

Please visit our FAQ page that should answer the bulk of your questions to get started.

What Can Be Lifted, Levelled, Void Filled and/or Stabilized?

Residential

Driveways

Sidewalks

Patios

Basement Floors

Garage Pads

Shop Floors

Pool Decks

Poured-In-Place, Formed Concrete Steps

Walkways

Landscaping Slabs

Any Slab-On-Grade Interior or Exterior Concrete

Commercial, Industrial & Agricultural

Joint Stabilization Void Filling

Machine Stabilization

Railroad Approach

Floating Dock Barrels

Tank Injection

Grain Bin Floors

Barn or Shop Floors

Airport Runways & Tarmacs

Rocking Concrete Floor Panels

Industrial Plant Slabs

Warehouse Slabs

Office & Retail Floors

Concrete Parkades

Gymnasiums & Classroom

Floors

Bus Shelters

Slab-On-Grade University Tunnels

Wheelchair Access Ramps

Government

City Roads

City Sidewalks

Settled Bridge Approach Concrete Slabs

Settled Concrete Roads, Highways, Runways, Tarmacs

Wash-Outs & Sink Holes

Construction Over Perma-Frost

Rocking Floor Panels

Abandoned Culverts, Pipes, and Ducts

Erosion Control

Soil Stabilization

Engineering

Insulating and Sealing of Electrical and Mechanical Vaults

Abandoned Culverts, Pipes and voids

Reactive Clays and Other Erosion Stabilization

Blast Rock Stabilization

Restoring Load Transfer to Heavy Traffic or Load Areas

Settled Decks and Aprons

Fixing Frictions on Friction Piles

Liquification Prevention

Secondary Containment

Space Filling in Tunnels During Sleeving Processes

Water infiltration/ Ex-Infiltration

Catch Basins

Deep Storm System Voids

Lift Stations

Weight Scales

Articles & Before and After Photos

Essential Guide to Care for Lifted Concrete

Learn essential tips for maintaining your concrete after lifting. Our comprehensive guide covers the best practices to ensure long-lasting, durable concrete slabs. Get expert advice from Slab-Jack Kings.

How to Fix a Sinking Concrete Slab With Polyurethane Foam

Discover the efficient and cost-effective method of fixing sinking concrete slabs with foam. Learn the process, benefits, and why it’s the preferred solution.

Tips to Prevent and How to Repair Cracks in Concrete Driveways

Learn how to prevent cracks in concrete driveways with our expert tips. Protect your investment and maintain the longevity of your driveway with proactive maintenance strategies.

Rescuing a Sinking Basement Floor: The Slab-Jack Kings Solution

Worried about a sinking basement floor? Learn how Slab-Jack Kings can quickly lift and level your basement floor with minimal disruption and cost.

Causes of Sunken Concrete and How to Prevent It

Why does concrete sink? In this article you’ll read about common causes of sunken concrete and how to prevent it from happening.

My Pool Deck Sounds Hollow! What should I do?

My Pool Deck Sounds Hollow Why Are Cracks Forming In My Pool Deck? Notice cracks forming in your pool deck? Have a baseball bat lying around? Some simple ways to find potential dangerous voids beneath pool decks starts with checking for cracks, critter-made holes...

Polyurethane Concrete Lifting Cost – Why Choose Foam vs Mud?

Discover the efficient, cost-effective method to fix sinking concrete slabs with foam. Learn the process, benefits, and why it’s preferred.

What CAN’T Be Raised With Foam or Mud?

Can All Concrete Be Restored? When is a slab too damaged to raise vs replace it? What CAN'T Be Restored With Foam Jacking or Mudjacking 1. Precast or hollow cast steps and staircases: Unfortunately we aren’t able to lift staircases like this. If you cannot see a slab...

How to Maintain Your Concrete After a Lift: The Exterior Post-Lift Maintenance Guide

How to Maintain Your Concrete After a Lift: The Exterior Post-Lift Maintenance Guide Raising the Surrounding Grade - Imperative! After an exterior concrete lifting job, the customer is responsible for raising any of the adjacent...

My Concrete Patio Is Sinking. What Do I Need To Do?

"My Concrete Patio Is Sinking." You need to contact the concrete lifting, foam jacking specialists-Slab-Jack Kings! Raise, level and stabilize your slab vs costly replacement. Save up to 85% of the replacement cost and use your patio again within a few hours! Before:...

Slab-Jack Kings Reviews